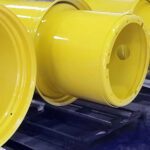

FIND THE PERFECT COLOR & IDEAL FINISH.

Powdura® RAL Series

Superior weatherability and TGIC-Free polyester powder coatings across 188 colors, available in gloss and satin sheens.

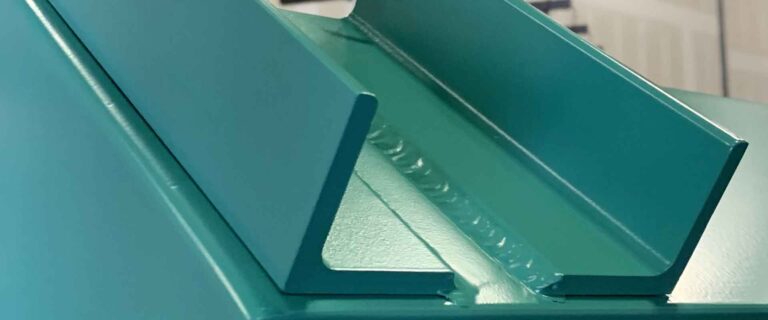

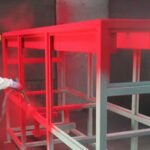

Equally as important are paint color and paint PERFORMANCE.

Architects, specifiers and building owners must determine which performance specification is required. In order to ensure the paint performance expected for a given application, one of three AAMA specifications should be referenced:

Our Standard interior specification

Sherwin Williams® Powdura RAL Series Satin SD Superdurable Polyester Powdercoat

Mid Grade level

Sherwin Williams® Powdura 4000 Superdurable Polyester Powdercoat

Highest grade level exterior specification.

Sherwin Williams® Powdura 5000 Fluoropolymer Powdercoat

Our Standard interior specification

Sherwin Williams® Powdura RAL Series Satin SD Polyester Powdercoat

Mid Grade level

Sherwin Williams® Powdura 4000 Superdurable Polyester Powdercoat

Highest grade level exterior specification.

Sherwin Williams® Powdura 5000 Fluoropolymer Powdercoat

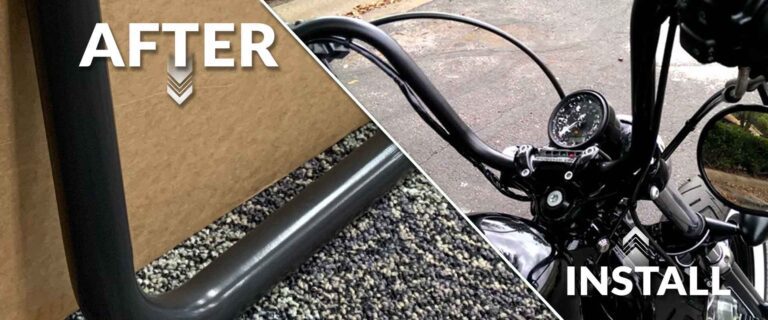

Coatings should be visibly free from flow lines, streaks, blisters or other surface imperfections in the dry-film state on exposed surfaces when observed at a distance of 10 feet (3 m) from the metal surface and inspected at an angle of 90 degrees to the surface.

*These specifications apply to South Florida outdoor exposure and laboratory accelerated testing results.